Glass Tempering

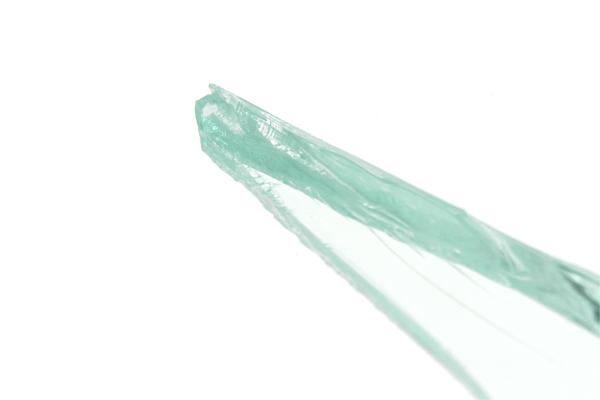

Unlike ordinary glass, the glass used in Futureglass products offers the reassurance of conformance to British Standard BS 6206A for maximum safety. Ordinary glass or annealed glass is a brittle material. This is due to the microscopic cracks that exist on the surface of the glass. When the glass breaks, it generally forms large dangerous shards which can cut deeply. An example of this is shown below from an inferior product. This is not the glass used by Futureglass.

The tempering process used to produce glass for Futureglass causes these microscopic cracks to close, making the glass four to five times stronger than annealed glass. This gives the glass a compression value greater than concrete.

If this toughened glass were ever to break, the stored energy is released and the increased bond between the molecules makes the glass shatter, forming small particles with dulled edges. This toughening process ensures that glass in Futureglass products offer the reassurance of conformance to British Standard BS6206A for maximum safety. An example of this is shown below.

The safety of key Futureglass products has been independently verified by FIRA (Furniture Industry Research Association) where the products were awarded a range certificate of safety. We are also in regular contact with Trading Standards to ensure that Futureglass continues to adopt best practice for maximum reassurance.